BANDSAW BLADE BREAK-IN PROCEDURE

GUIDES FOR PURCHASING A BANDSAW MACHINE

October 15, 2020

WHAT IS THE DIFFERENCE BETWEEN HM AND HSS CIRCULAR SAW BLADES?

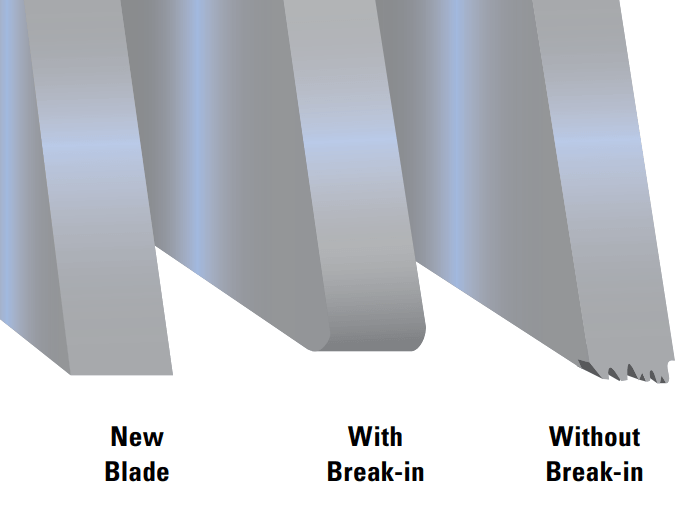

April 18, 2022The importance of breaking in a new blade should not be underestimated. It can mean the difference between success and failure of your bandsaw blade.

Proper break-in of your bandsaw blade will give you a more uniform blade life. It will make it easier to judge the overall blade life and performance.

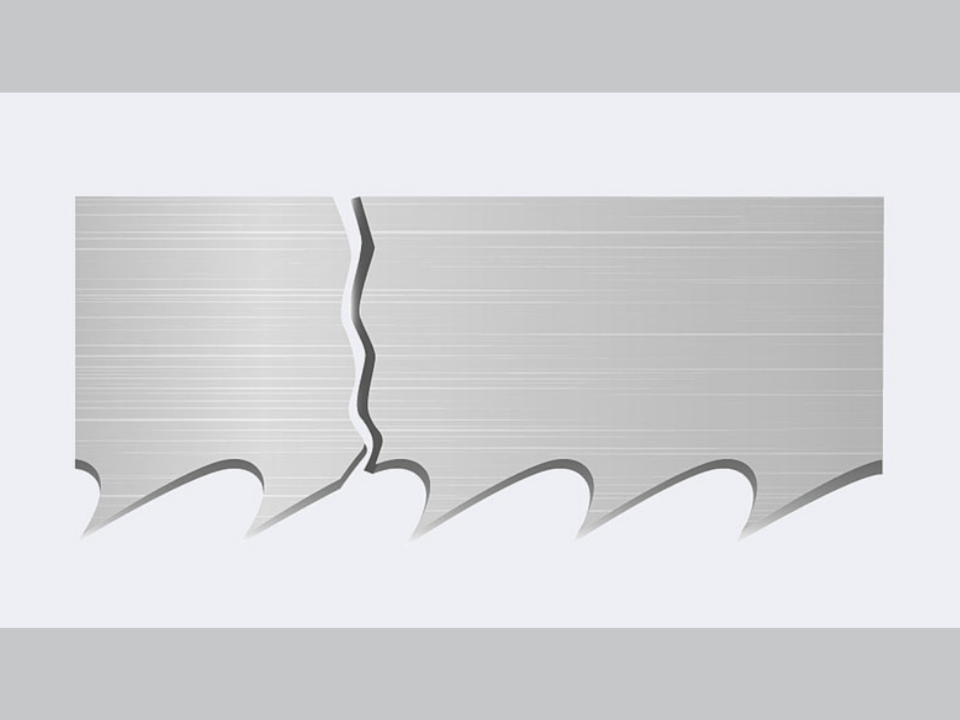

One should always break-in a blade when first installed to remove the sharp edge. Breaking-in the bandsaw blade will give you a much longer blade life and you will not have as many problems with breaking/stripping teeth, or crooked cuts.

The following are a few successful ways to properly break-in bandsaw blades.

Procedure 1

1. Set the speed of the bandsaw blade according to your cut charts or the blade manufacturer's Recommended Speeds list.

2. Reduce the feed pressure and/or head drop rate by 25% of the regular production rate for the first one hundred square inches.

Procedure 2

1. Set the speed of the bandsaw blade according to the size and type of material to be cut.

2. Reduce the feed force to the minimum feed possible to maintain a chip.

3. Gradually increase the feed pressure until the desired cutting rate is acquired.

Procedure 3

1. Reduce the blade speed and feed force by 25%.

2. Gradually increase both speed and feed until the desired cutting rate is achieved.

Procedure 1

1. Set the speed of the bandsaw blade according to your cut charts or the blade manufacturer's Recommended Speeds list.

2. Reduce the feed pressure and/or head drop rate by 25% of the regular production rate for the first one hundred square inches.

Procedure 2

1. Set the speed of the bandsaw blade according to the size and type of material to be cut.

2. Reduce the feed force to the minimum feed possible to maintain a chip.

3. Gradually increase the feed pressure until the desired cutting rate is acquired.

Procedure 3

1. Reduce the blade speed and feed force by 25%.

2. Gradually increase both speed and feed until the desired cutting rate is achieved.