GUIDES FOR PURCHASING A BANDSAW MACHINE

HOW TO CHOOSE CORRECT TOOTH PITCH

October 15, 2020

BANDSAW BLADE BREAK-IN PROCEDURE

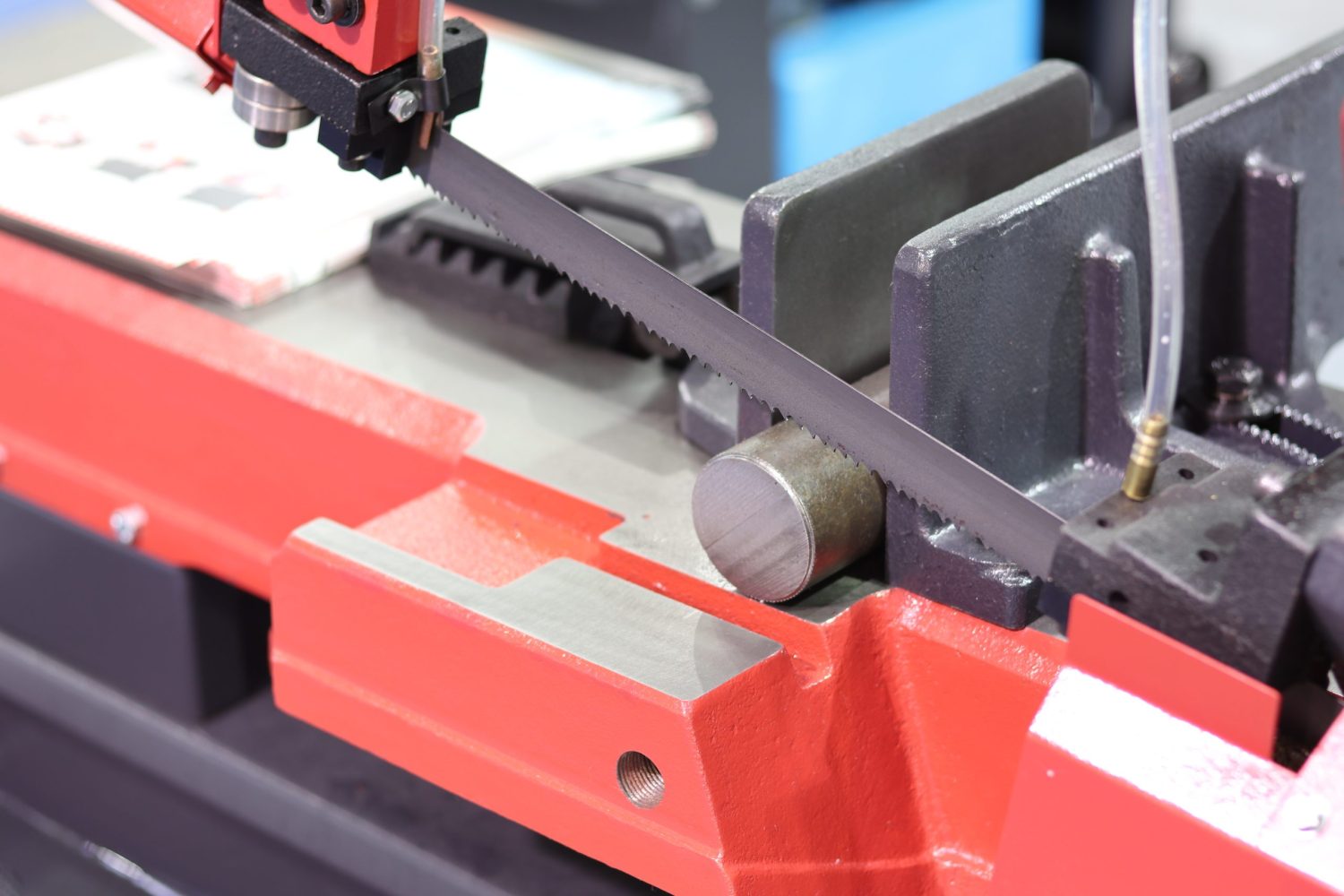

April 24, 2021Purchasing a bandsaw machine requires various sort of information, whether the machine is going to be used in a small investment or a large scale project, there are some essential factors which must be considered. One of the first steps is to consider the level of cuttings required per day. Bandsaws vary from simply manually controlled, to fully automatic and hydraulic machines. As the volume and amount of materials increase, the power and automation of the saw become critical. Scissor Type Bandsaw machine cutting a solid.

Types Of Bandsaw Machines

Automatic bandsaws offer a fully automated process for feeding and cutting the material. The operation process of the saw is a PLC which allows the operator to select a job from a programmable memory when choosing an automatic saw it is important to look at factors such as motor capacity, weight of the machine and blade size.

Semi-automatic machines have a similar procedure to the automatic ones, and the only difference is that the cutting operation must be done by an operator. The automatic controls refers to the automated descent and return of the saw bow head and clamping of the material is often controlled hydraulically.

manual bandsaws are often very easy to use and a constant operator is needed to work with the machine. As the bow does not return up after the cutting procedure, you need to manually control the move. Manual saws are ideal for small workplaces and end of production processes.

It is also important to consider the following features:

The Size of Material

When choosing a machine it's vital you get the sizing right. For example, a manual HD 375LR bandsaw machine will cut 375mm and will cut a diameter of 300mm, but it's always best to add a bit on to your calculations as you don't want to have a machine working at its limit. Remember that if the machine mitres, this will cut down the capacity too, so you need to budget for that as well.

Operations

When buying a machine, it's important to decide if you want a manual machine, a hydraulic lift machine, a semi-automatic or an automatic bandsaw. The more expensive machines will lift up automatically after the cut, saving you time and effort if you have a lot of cutting to do.

Mitre Cuts

You can choose machines that mitre left and right, or which mitre both left and right. If you are looking for a cheaper machine and don't need many mitre cuts, you could select a machine that mitres one way, and if necessary, flip the material to mitre the other way.

Blade Speeds

Blade speeds are very important in deciding which machine you need. The cheaper machines have two speeds -the slow speed is usually around 35 metres per minute and the fast speed is around 70 metres per minute. This is acceptable for stainless steel and mild steel. However, if you're cutting a wide variety of materials, you can choose a machine with a variator and the machine blade will cut at a numer of different speeds to suit all metals.

Clamping

The more expensive machines, will clamp the work automatically - when you press the start button, they go down, cut the piece, go back up and unclamp. All you need to do is to feed the material through and press start.

Finally, a fully automatic bandsaw will feed the material through and cut it to length, greatly increasing productivity