FACTORS THAT AFFECT THE COST OF CUTTING

BANDSAW BLADES PROBLEMS AND THEIR TROUBLESHOOTING

April 19, 2022

HOW TO CHOOSE A CIRCULAR SAW BLADE

April 24, 2022There are several factors that affect band sawing efficiency; tooth design, band speed, feed rates, vise loading, lubrication, the capacity and condition of the machine, and the material you are cutting. This article will perfectly explain you how these factors may affect the cutting process, and it may help you decide how to set these variables so that you can optimize your cutting operation.

How chips are made

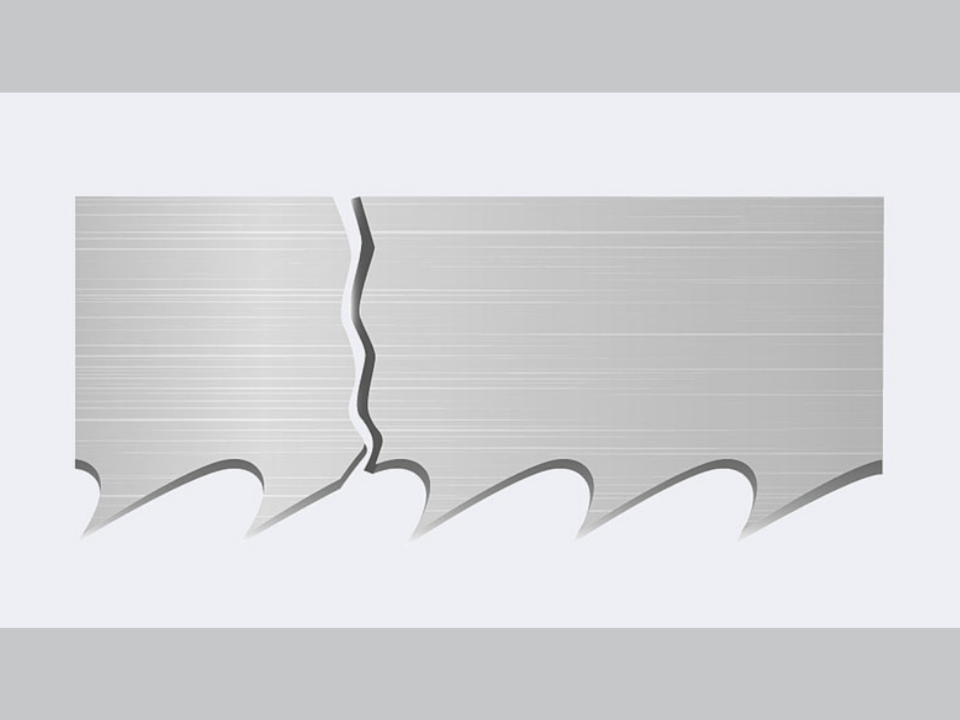

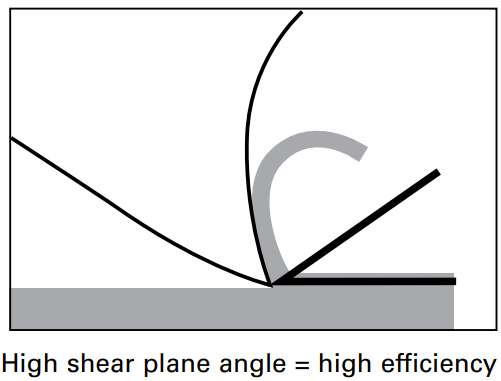

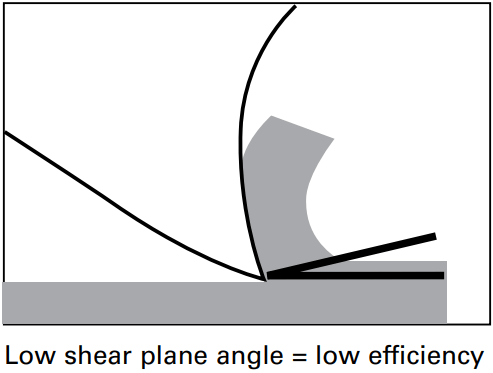

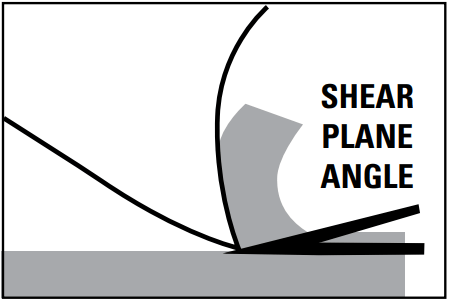

If you were to look at a blade cutting metal under a microscope, you would see the tooth tip penetrating the work and actually pushing, or shearing, a continuous chip of metal. the angle at which the material shears off is referred to as the "shear plane angle." This is perhaps the single most important factor in obtaining maximum cutting efficiency.Generally, with a given depth of penetration, the lower the shear plane angle, the thicker the chip becomes, and the lower the cutting efficiency. The higher the shear plane angle, the higher the efficiency, with thinner chips being formed.

Shear plane angle is affected by work material, band speed, feed, lubrication and blade design as shown in the following sections.

Feed

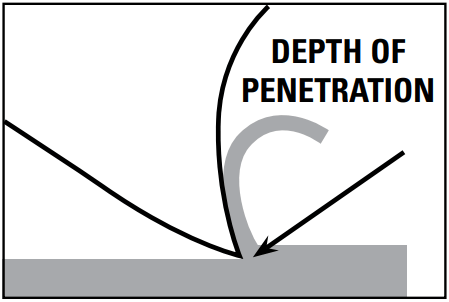

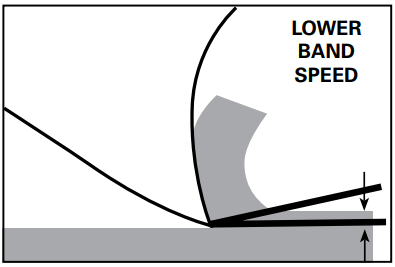

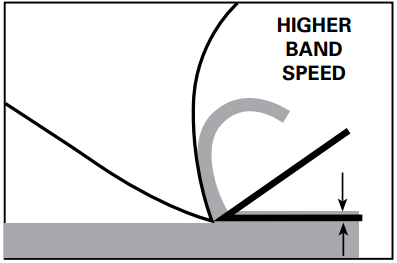

Feed refers to the depth of penetraion of the tooth into the material being cut. For cost effective cutting, you want to remove as much material as possible as quickly as possible n=by using as high a feed rate/pressure as the machine can handle. However, feed will be limited by the machinability of the material being cut and blade life expectancy.A deeper feed results in a lower shear plane angle. Cutting may be faster, but blade life will be reduced dramatically. Light feed will increase the shear plane angle, boy increase cost per cut.

Band speed

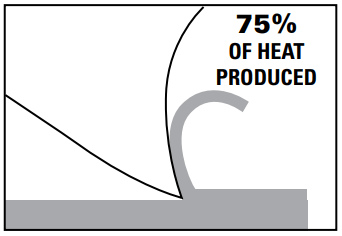

Band speed refers to the rate at which the blade cuts across the face of the material being worked. A faster Band speed achieves a higher, more desirable shear plane and hence more efficient cutting. This is usually stated as FPM (feet per minute) ot MPM (meters per minute).Band speed is restricted, however, by the machinability of the material and how much heat is produced by the cutting action. Too high a band speed or very hard metals produce excessive heat, resulting in reduced blade life.

To understand if you are using the right band speed, look at the chips, check their shape and color. The goal is to achieve chips that are thin, tightly curled and warm to the touch. If the chips have changed from silver to golden brown, you are forcing the cut and generating too much heat. Blue chips indicate extreme heat which will shorten blade life.

Vise Loading

The position in which material is placed i the vise can have a significant impact on the cost per cut. Often, loading smaller bundles can mean greater sawing efficiency.All machines have a stated loading capacity, but the practical level is usually lower, 1/2 or 1/3 as much, depending on the material being cut.

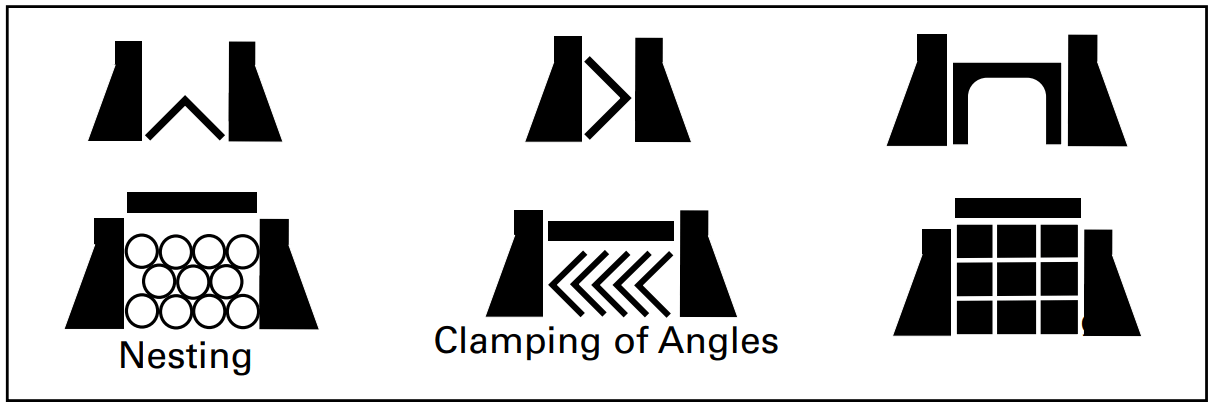

When it comes to cutting odd-shaped material, such as angles, I-beams, channel, and tubing, the main point is to arrange the materials in such a way that the blade cuts throughout the entire distance of cut.

The following diagrams suggest some cost-effective ways of loading and fixturing. Be sure, regardless of the arrangement selected, that the work can be firmly secured to avoid damage to the machine or injury to the operator.

Lubrication

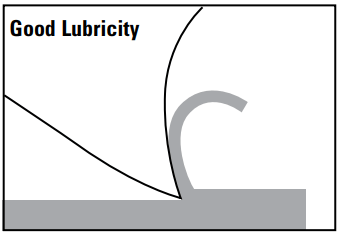

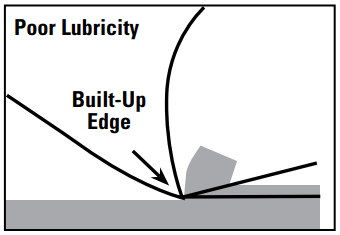

Lubrication is essential for long blade life and economical cutting. Properly applied to the shear zone, lubricant substantially reduces heat and produces good chip flow up the face of the tooth. Without lubrication, excessive friction can produce heat high enough to weld the chip to the tooth. This slows down the cutting action, require more energy to shear the material and can cause tooth chipping or stripping which can destroy the blade.