HM (Hard Metal) Wood & MDF Circular Saw Blades

Circular saws are hand-held saws featuring a circular saw blade.They are generally used by placing the saw on the piece of wood that is being cut, and you can either cut by eye or by using some kind of jig to help cut a straighter line. Circular saws also allow you to change the height and angle of the cut, allowing you to make all the same types of cut. Circular saws are generally more affordable than table saws, and they are also much safer. While it is perfectly possible to cause a serious injury with a circular saw, they are still much safer than table saws.

A circular saw is one of the most popular and widely used power saws that can help you cut through various kinds of materials, including wood, plastic, metal, etc. It features a toothed or abrasive blade that has to be guided downwards on the workpiece that you have to cut. Usually, circular saws are mounted onto a work table, but they can also be found in handheld variants.

The most important component of the circular saw is its blade, and the type of blade you use for cutting through different materials determines how smooth the operation would be.

Things to consider before choosing a circular saw blade:

1Number of Teeth

Generally, blades with more teeth will provide a smoother, finer cut whereas blades with fewer teeth will provide a rougher cut. The benefit of fewer teeth is faster cutting and a lower price.

2Gullet Size

The gullet is the space between the teeth, the size and depth of which determine how much waste material is cleared out as the blade spins. You can quickly see that the gullet size is a function of the number of teeth.

3Hook or Rake Angle

Hook or rake is the position of the tooth as it contacts the cutting surface. A positive angle points down toward the wood’s surface aggressively removing waste material, resulting in a faster but rougher cut.As you might imagine, negative hook or rakes cut less aggressively and don’t self-feed which creates a smoother finish, but they also cut won’t cut as quickly or remove as much waste. The angle can also be neutral.

4Bevel Angle

This important distinguishing factor is the angle of the tooth across or perpendicular to the blade’s spin. The higher the bevel angle, the cleaner and smoother the cut.

5Kerf

This is the width of the tooth at its widest point and therefore the width of the cut. The thinner kerf produced less resistance in the cut and so was better-suited for the power needs of those saws.

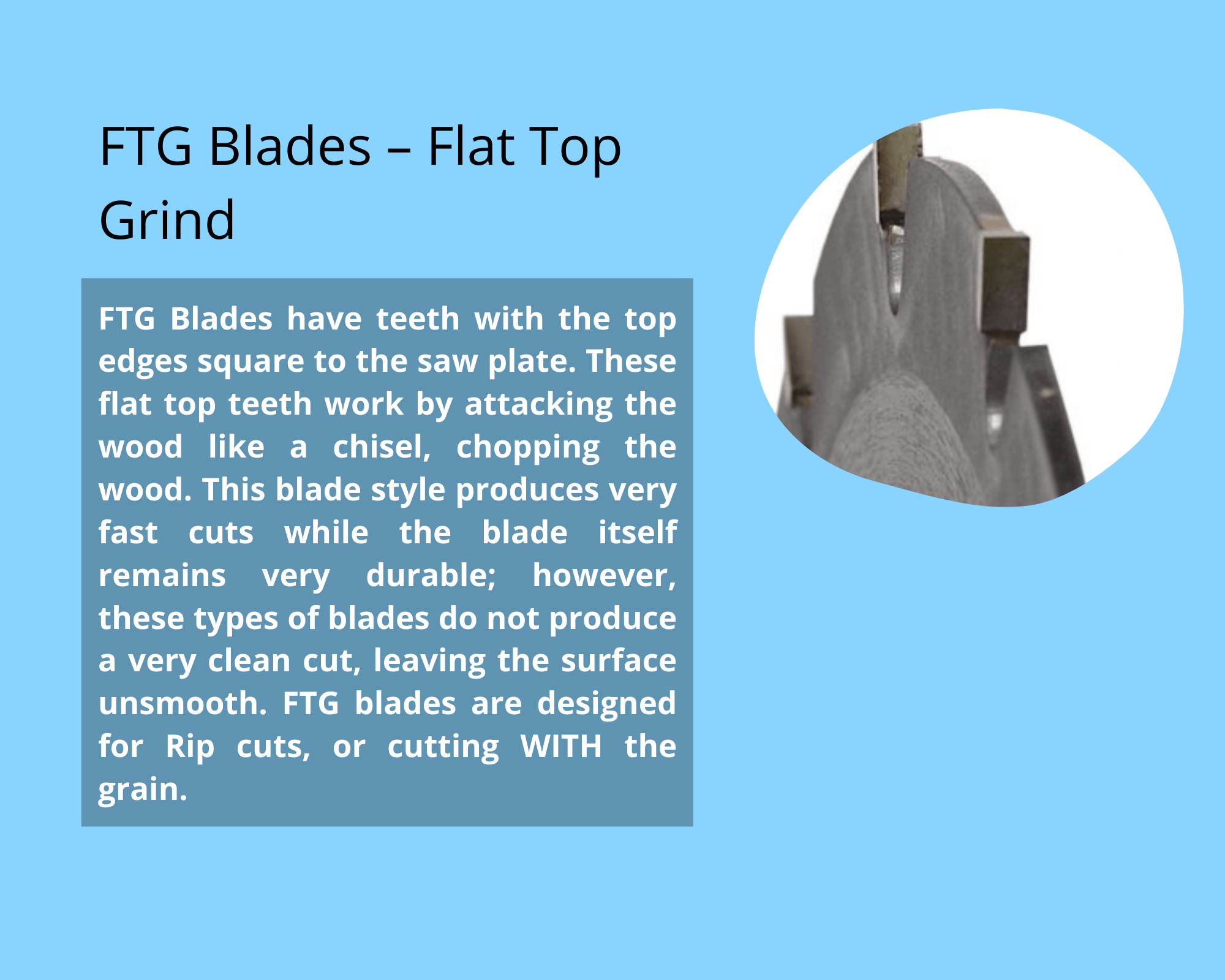

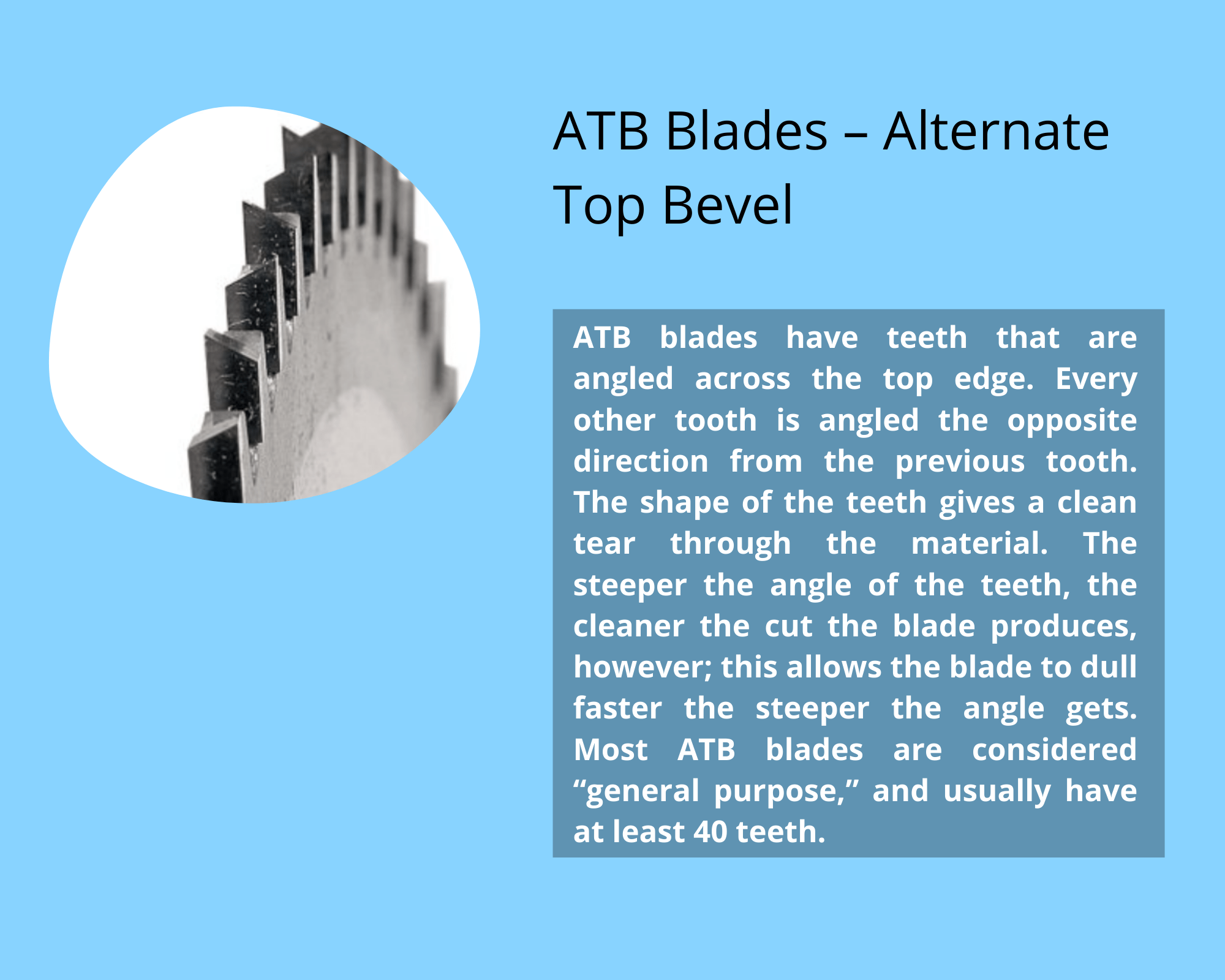

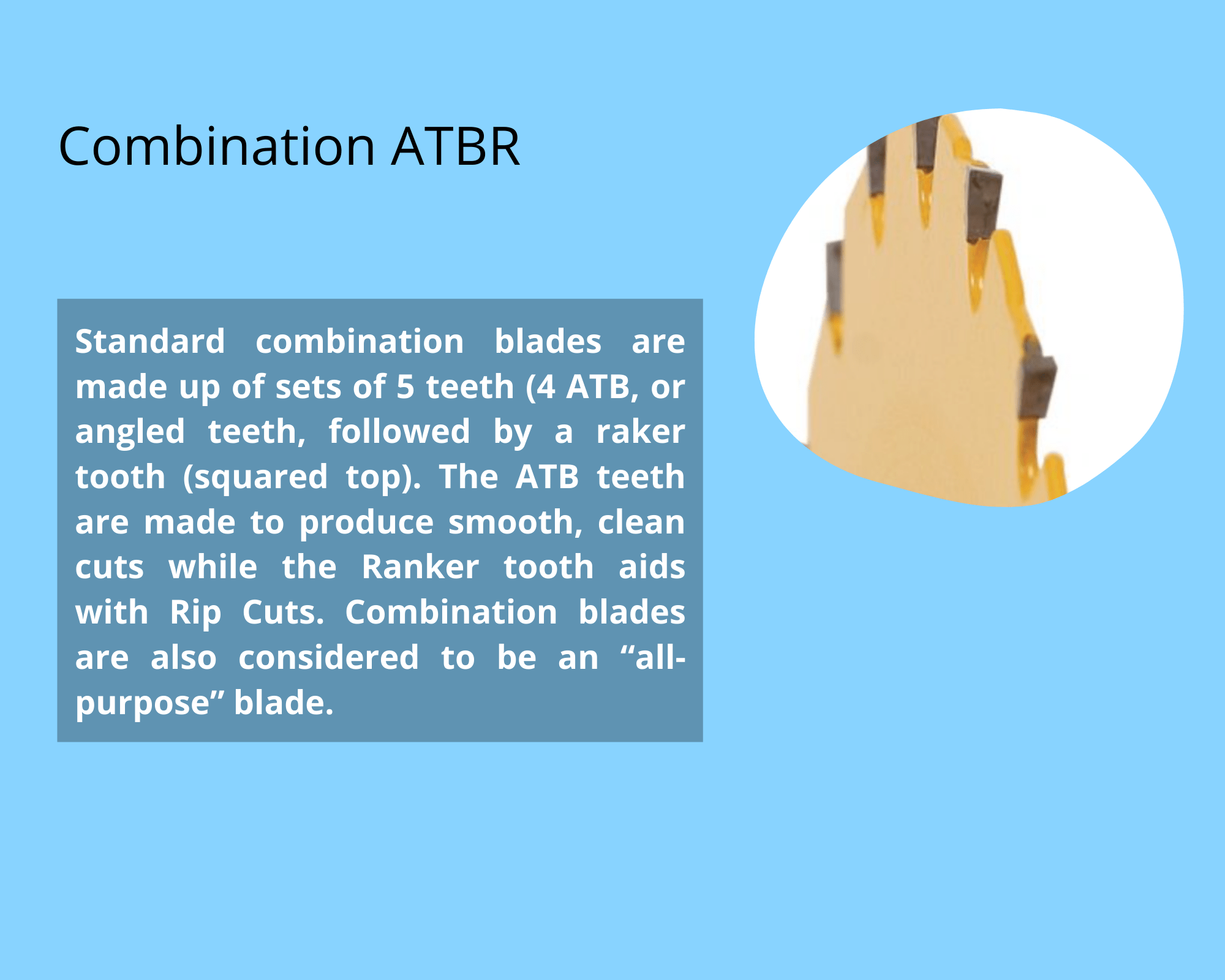

There are Four Basic Types of Circular Saw Blades:

The table below shows our available sizes, other dimensions are upon request:

| Diameter | Thickness | Bore | Z |

|---|---|---|---|

| 200 | 3.0 | 32 | 48 |

| 200 | 3.0 | 32 | 64 |

| 225 | 3.2 | 32 | 56 |

| 250 | 3.2 | 32 | 60 |

| 250 | 3.2 | 32 | 80 |

| 275 | 3.3 | 32 | 64 |

| 300 | 3.3 | 32 | 72 |

| 300 | 3.3 | 32 | 84 |

| 300 | 3.3 | 32 | 96 |

| 330 | 3.4 | 32 | 72 |

| 330 | 3.4 | 32 | 96 |

| 350 | 3.4 | 32 | 84 |

| 350 | 3.4 | 32 | 96 |

| 350 | 3.4 | 32 | 112 |

| 370 | 3.6 | 32 | 90 |

| 400 | 3.6 | 32 | 96 |

| 400 | 3.6 | 32 | 120 |

| 420 | 3.8 | 32 | 96 |

| 450 | 3.8 | 32 | 96 |

| 450 | 3.8 | 32 | 112 |

| 500 | 4.2 | 32 | 112 |

| 500 | 4.2 | 32 | 120 |