Pivot-Type Bandsaw Machines

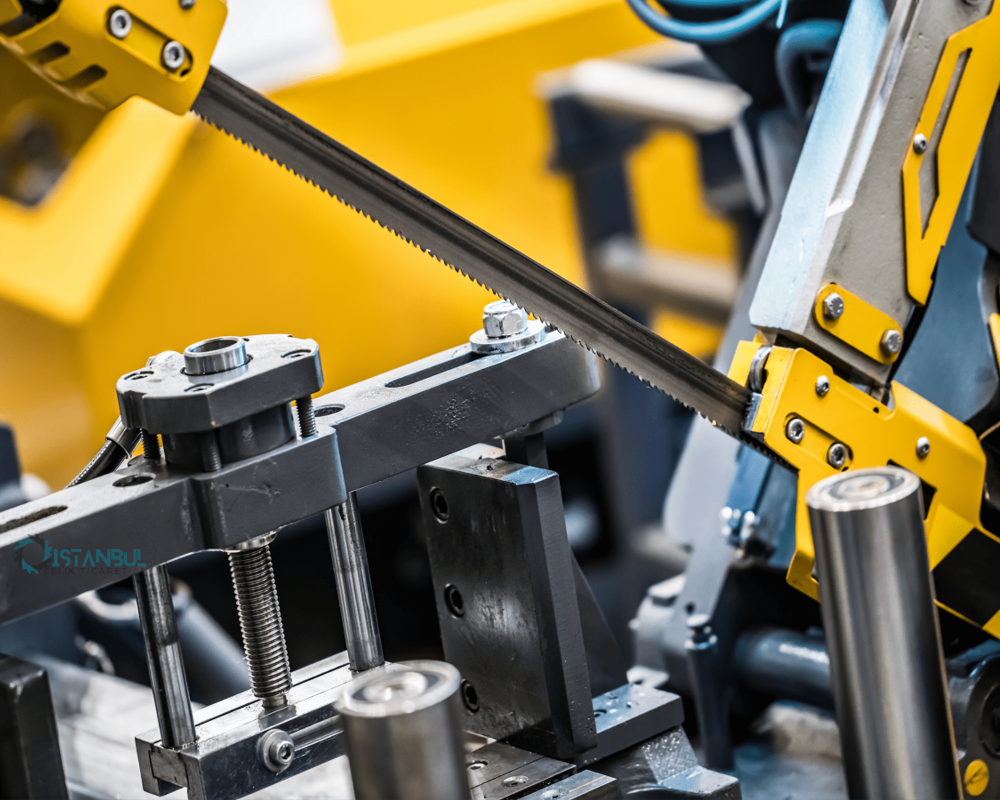

The first type of bandsaw machines based on their shape to introduce, are Pivot-Type bandsaw machines. These saws cut through the stock horizontally and so, they got their name from their operational type. A horizontal saw places the stock on the vice next to the band saw bed. Then the blade comes down horizontally to cut down through the stock.The horizontal band saws are used to cut large timbers into a smaller and manageable size. Typically, the Horizontal bandsaw machines are floor-mounted machines that are employed for jobs like simple cutting of solid steel, tubing, and other odd-shaped raw material stock.

How Does a Pivot-Type Bandsaw machine Operate?

The bandsaw blades in Pivot-Type bandsaw machines are driven by an electric motor, a belt and pulley mechanism is employed to drive the motor. This mechanism creates room for the speed of the blades to be adjusted in discrete stages according to requirements.

The cutting position of the bandsaw steel blade in a Pivot-Type bandsaw machine is horizontal and it makes cuts into the stock with a downward motion. The drive and idler wheels are positioned along the length of the machine on the machine frame, which pivots from a corner on the sawing machine bed. The material stock which is to be cut is mounted in a vise mounted on the bed of the machine.

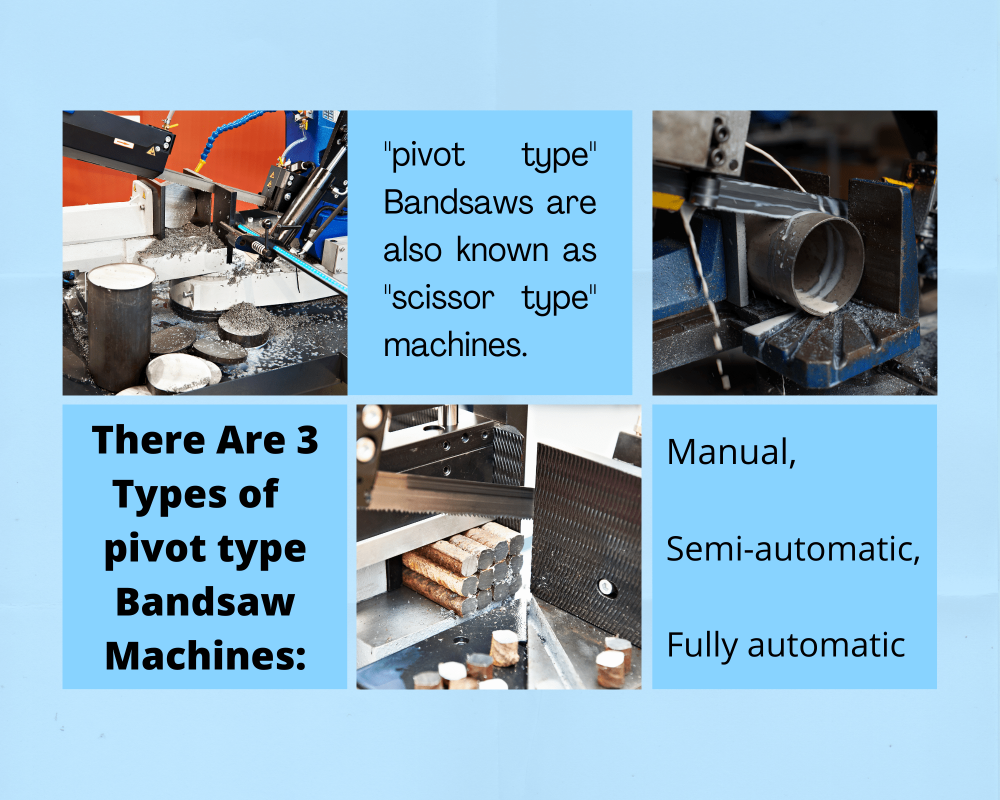

Pivot-Type Bandsaw Machines Categories

Pivot-Type are commonly categorized into three groups: Manual, Semi-automatic and Fully automatic.

Manual: In manual bandsaw machines, the pivot Pull down requires the operator to manually lift the saw head up and down. This type of machines have already been obsolete.

Semi-automatic: Semi automatic saws require the operator to move the material manually for each cut whilst the saw takes care of the cutting with automatic gravitational downfeed and head return.

Fully automatic: Automatic saws are fully programmable and ideal for mass production cutting and can be left unattended for overnight production.

Parts of Band Saw Machine

- To avoid some harmful impacts on human health, a bandsaw machine is generally equipped with brushes or brush wheels for being able to prevent chips from getting caught between the blade teeth and causing damage.

- In order to cool the saw blade, the bandsaw machine must be designed and equipped with a cutting fluid circuit containing coolant liquid. The coolant liquid can wash away the waste material chips while keeping the saw blade cool as well as properly lubricated.

- Furthermore, the band saw machines which are controlled by PLC or CNC systems can be partly automated as well.

- Some automatic band saw machines that are equipped with digitally operated control units cannot just cut faster, but also cut in a more precise manner with higher accuracy, and eventually perform complex cutting operations like bevel cutting tasks.

- As a result, most of the modern bandsaw machines are pre-equipped with digital CNC controllers in order to adapt to today’s manufacturing requirements and standards.

If you are thinking of buying a new bandsaw, it's important to consider the following features: