HSS EMO5 Circular Saw Blades

Circular saws in high speed steel (5% cobalt content) suitable for cutting-off steels and alloys with hardness above 800 N/mm2. The saw blades are used on manual, semi-automatic and fully automatic sawing machines to cut tubes and pipes, open sections and solid sections up to 200 mm.

ELEMENTS AND THEIR EFFECTS

High Speed Steel saws are manufactured with a high content of tungsten and molybdenum. After heat treatment, these elements ensure good hardness and adequate toughness. A certain percentage of tungsten is essential to create the correct the correct quantity of very hard wear-resistant carbides in order to reduce tool wear especially in extreme working conditions. The tungsten also increases the mechanical endureance of the tool, increasing cutting performance and preventing austenitic grain enlargment. The molybdenum is essential to guarantee the formation of a fine martensitic structure; it also increases tool tenacity and maintains high mechanical resistance. Vanadium is the element that forms the hardest wear-resistant carbides of all alloys.

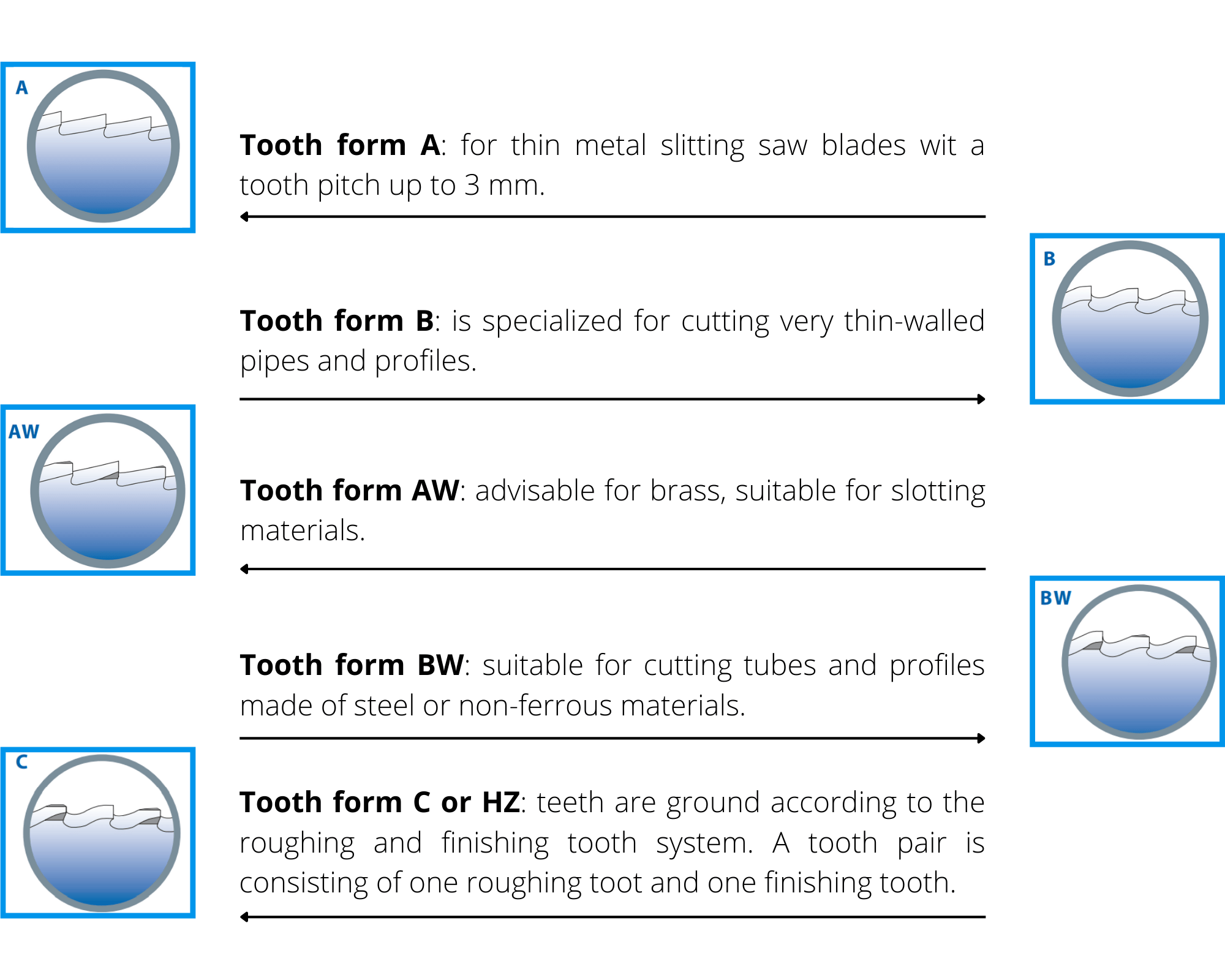

Tooth Forms:

Technical Reccomendations:

| Materials | Cutting speed | Feeding per tooth | Cutting angle | Clearance angle | HSS type |

|---|---|---|---|---|---|

| Steel (solid material) up to 500 N/mm2 | 30 - 50 | 0.05 - 0.08 | 18 - 20 | 8 - 12 | DMO5 |

| Steel (pipes and profiles) up to 500 N/mm2 | to 240 | 0.08 - 0.12 | 18 - 20 | 8 - 12 | DMO5 |

| Steel (solid material) up to 800 N/mm2 | 20 - 40 | 0.03 - 0.06 | 15 - 17 | 6 - 8 | DMO5 |

| Steel (pipes and profiles) up to 800 N/mm2 | to 120 | 0.05 - 0.08 | 15 - 18 | 6 - 8 | DMO5 |

| Steels up to 1200 N/MM | 12 - 25 | 0.03 - 0.05 | 14 - 16 | 6 - 8 | EMO5 |

| Stainless steels (solid materials) | 10 - 25 | 0.04 - 0.07 | 14 - 16 | 6 - 8 | EMO5 |

| Stainless steels (pipes and profiles) | to 50 | 0.06 - 0.1 | 16 - 18 | 6 - 8 | EMO5 |

| Cast irons | 15 - 25 | 0.07 - 0.12 | 16 - 18 | 6 - 8 | EMO5 |

| Alluminium and alluminium alloys (solid materials) | 600 - 900 | 0.05 - 0.1 | 22 - 25 | 10 - 12 | DMO5 |

| Alluminium and alluminium alloys (pipes and profiles) | 800 - 1200 | 0.07 - 0.12 | 22 - 25 | 10 - 12 | DMO5 |

| Bronze | 40 - 120 | 0.04 - 0.06 | 16 - 18 | 8 - 10 | DMO5 |

| Copper | 100 - 400 | 0.04 - 0.06 | 20 - 22 | 10 - 12 | Dmo5 |

| Brass | 150 - 400 | 0.04 - 0.06 | 14 - 16 | 8 - 10 | DMO5 |