M51 Bi Metal Bandsaw Blades

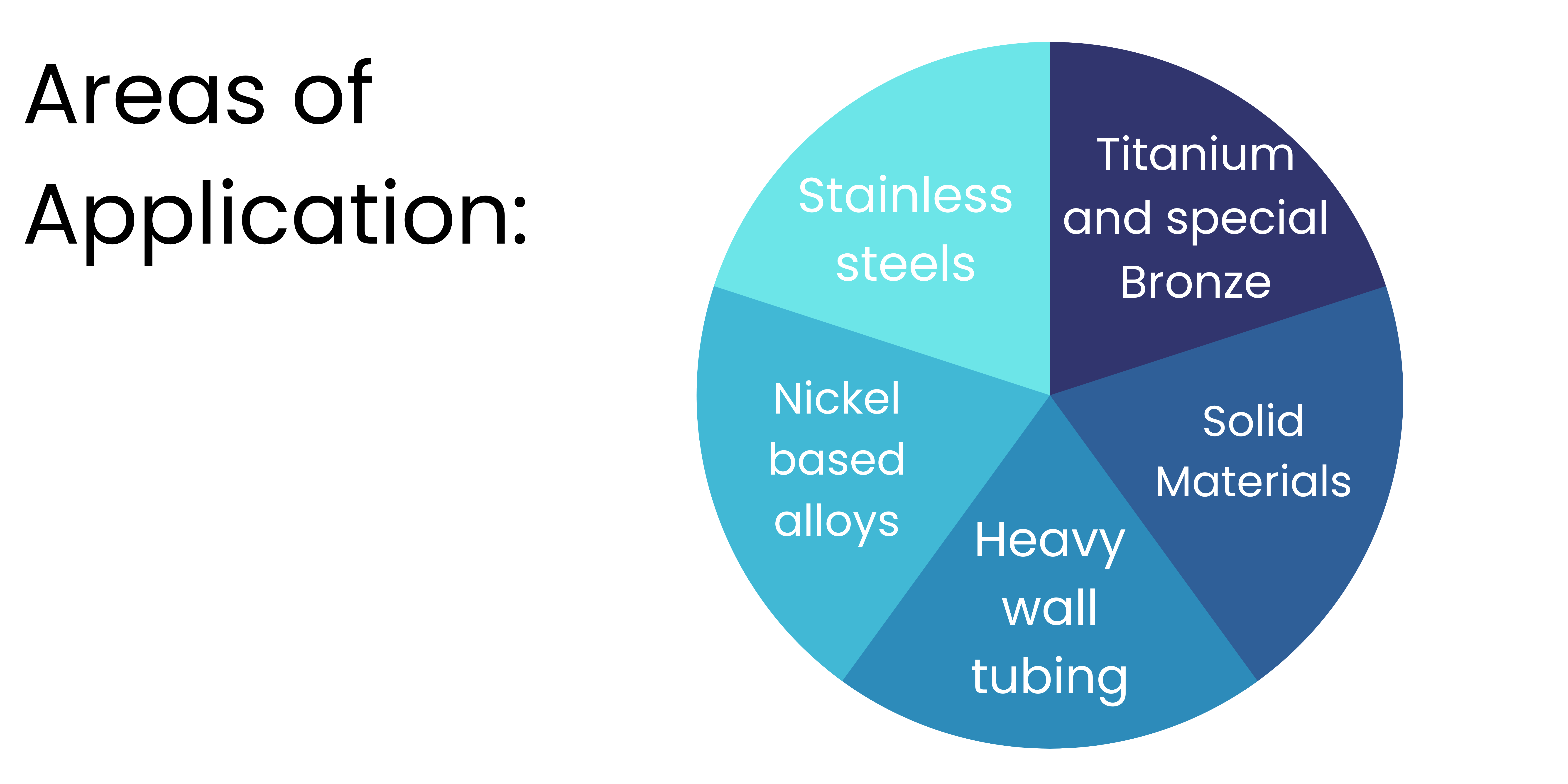

Bi Metal bandsaw blade made of 4% high chrome alloyed tenacious backing material and a HSS cutting edge made of HSS M51 with s cobalt content of 10% each having a hardness of 69 HRC.

The higher alloyed cutting edge is designed to cut high strength steel grades. Higher resistance against thermal and abrasive wear increases the blade life especially cutting long cross sections.

M51 BANDSAW BLADES DESCRIPTION

- M51 has been designed for use in heavy duty cutting applications.

- The cutting performance of the high speed steel teeth is greatly increased through alloying with cobalt and tungsten.

- These alloying elements substantially increase the heat resistance as well as the wear resistance.

Features

1Flexibility

The blade backer of Bi Metal bandsaw blade consists of a special alloyed spring steel. highly flexible at a hardness of about 50 HRC.

2Hardness and wear resistance

Tooth tips made of hardened HSS steel quality obtained due to well-balanced hardening and fixed structure resulting in high wear resistance.

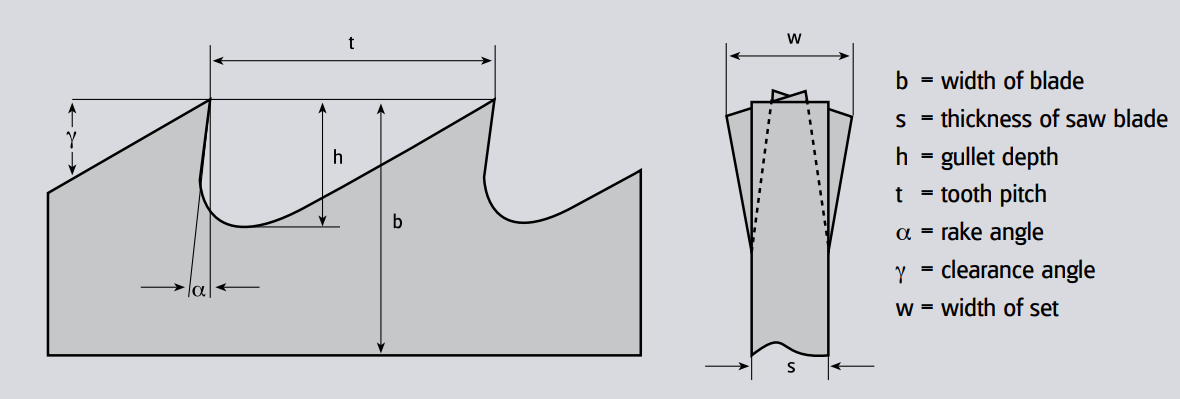

Band Saw Geometry:

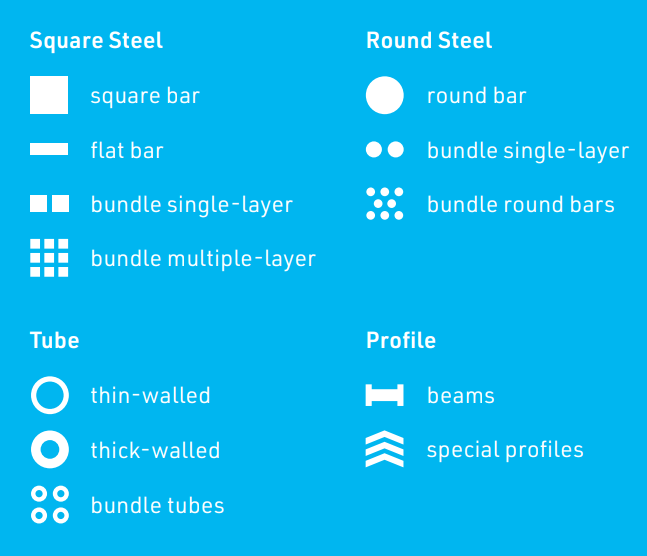

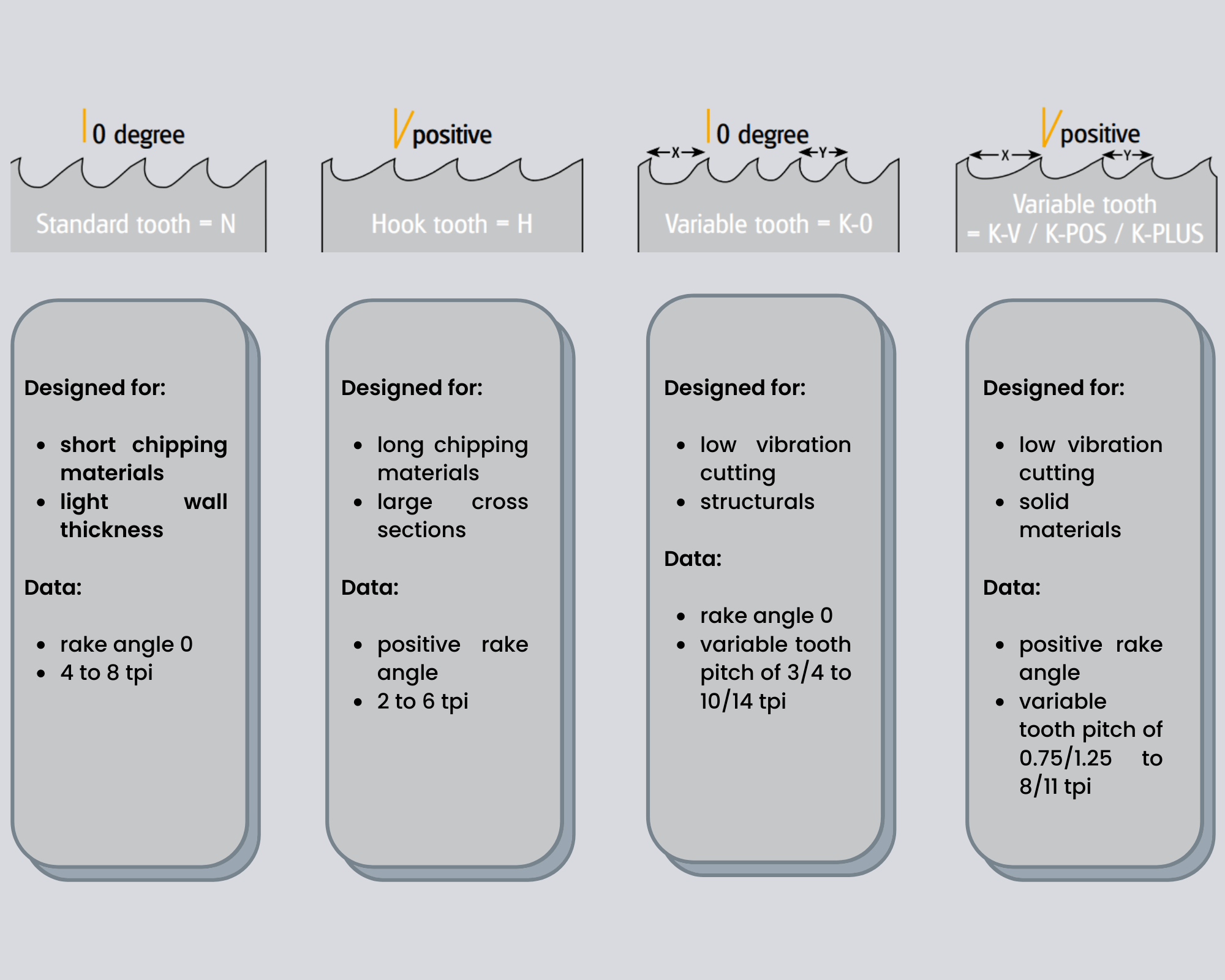

Tooth forms:

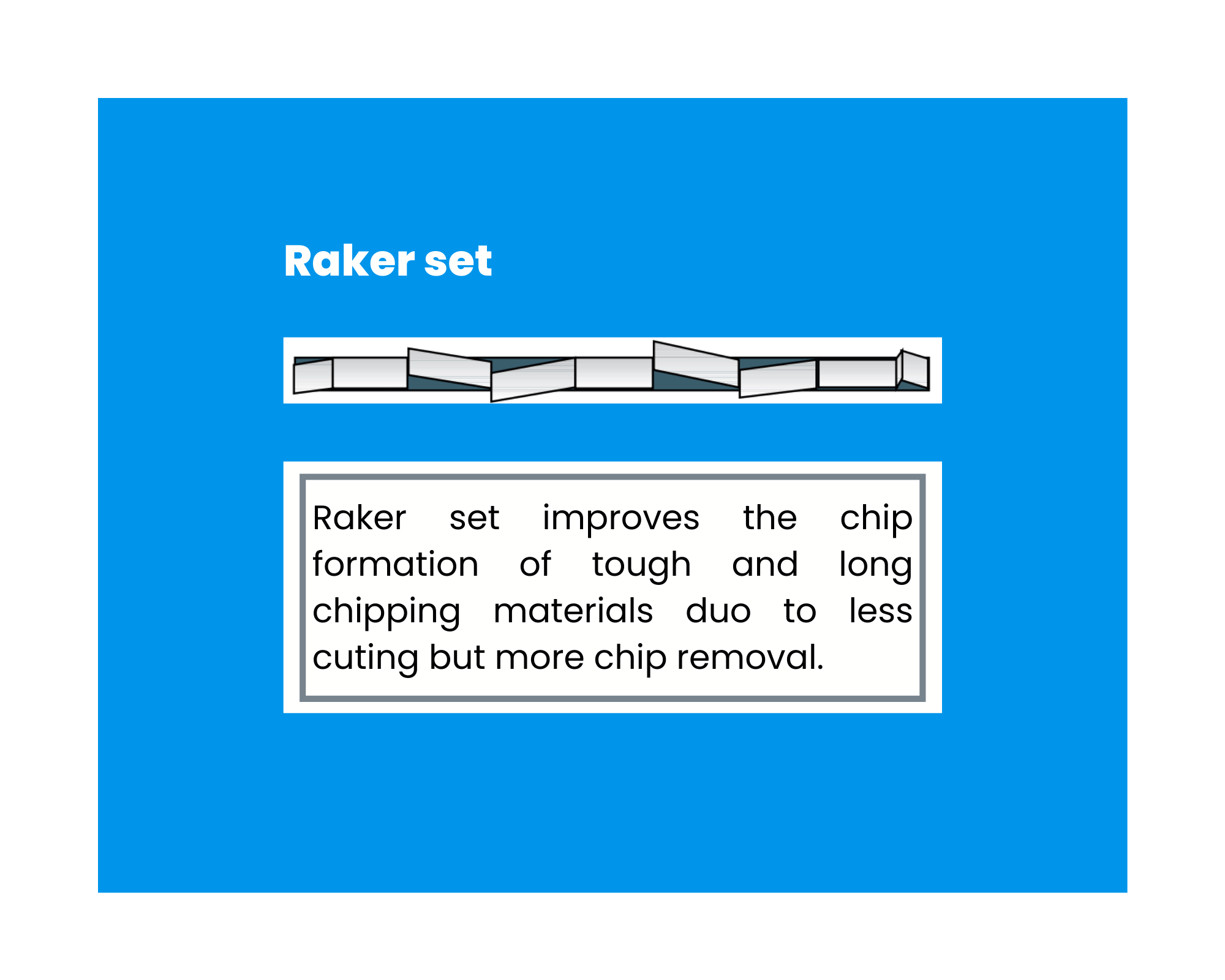

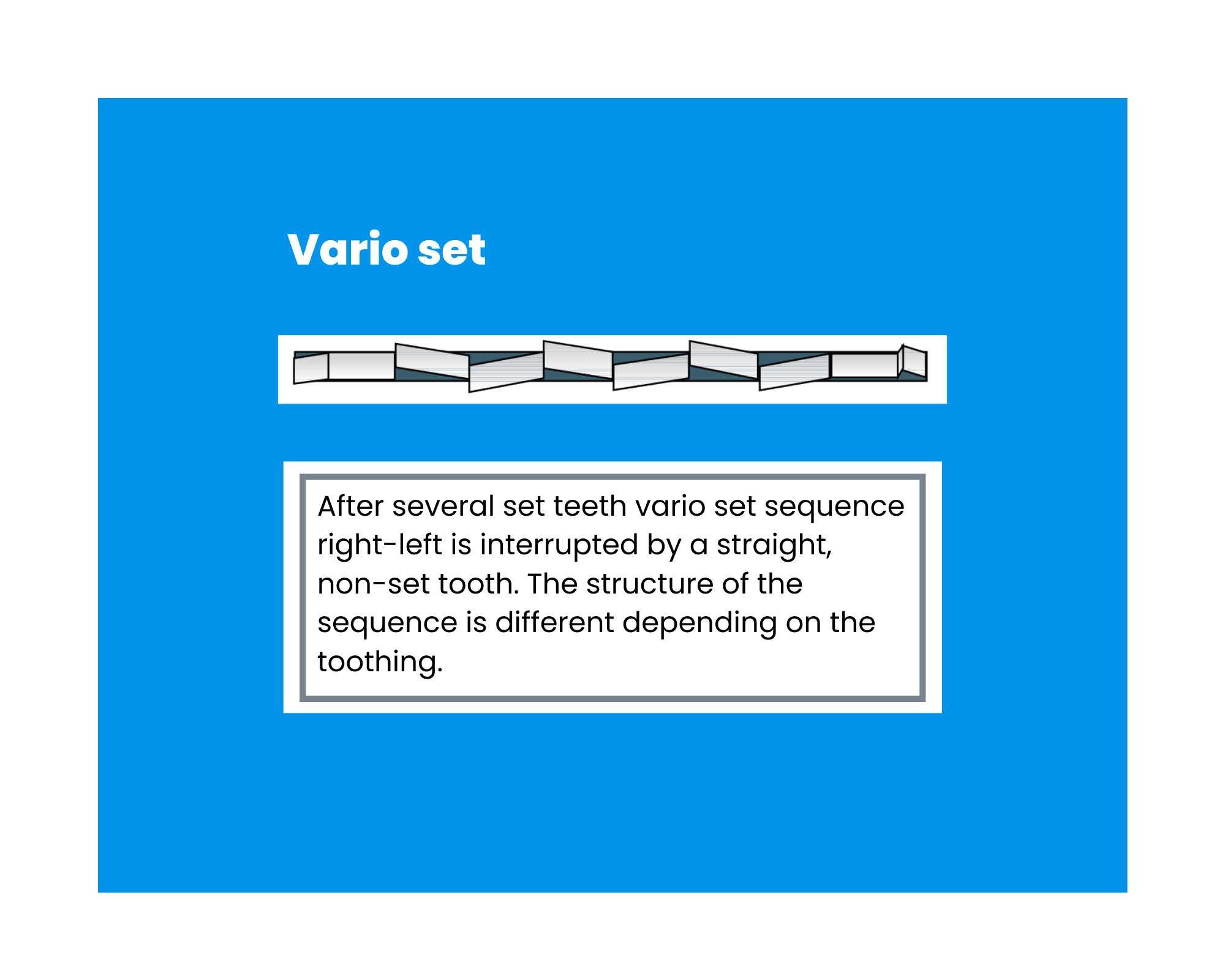

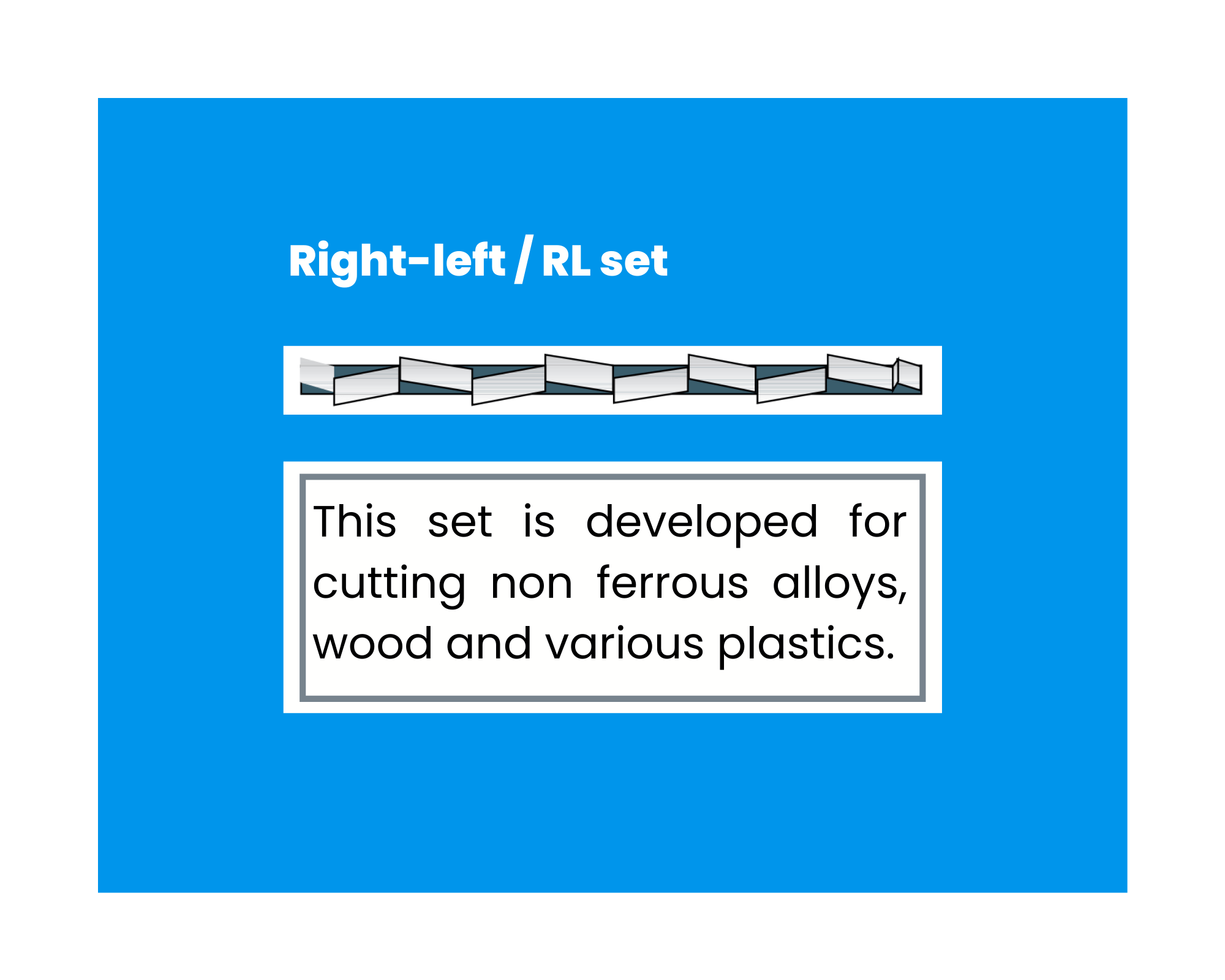

Tooth set

You must never ignore the importance of choosing the right tooth set, following section will help you gain information about about different types of sets on a band saw blade.

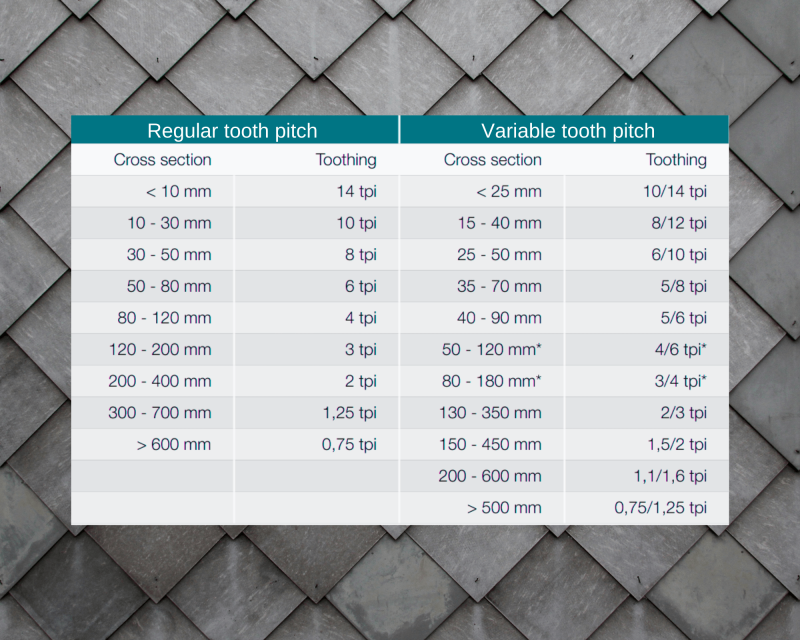

Recommendations For Tooth Selection

For Solid Material:

For Tubes And Structurals:

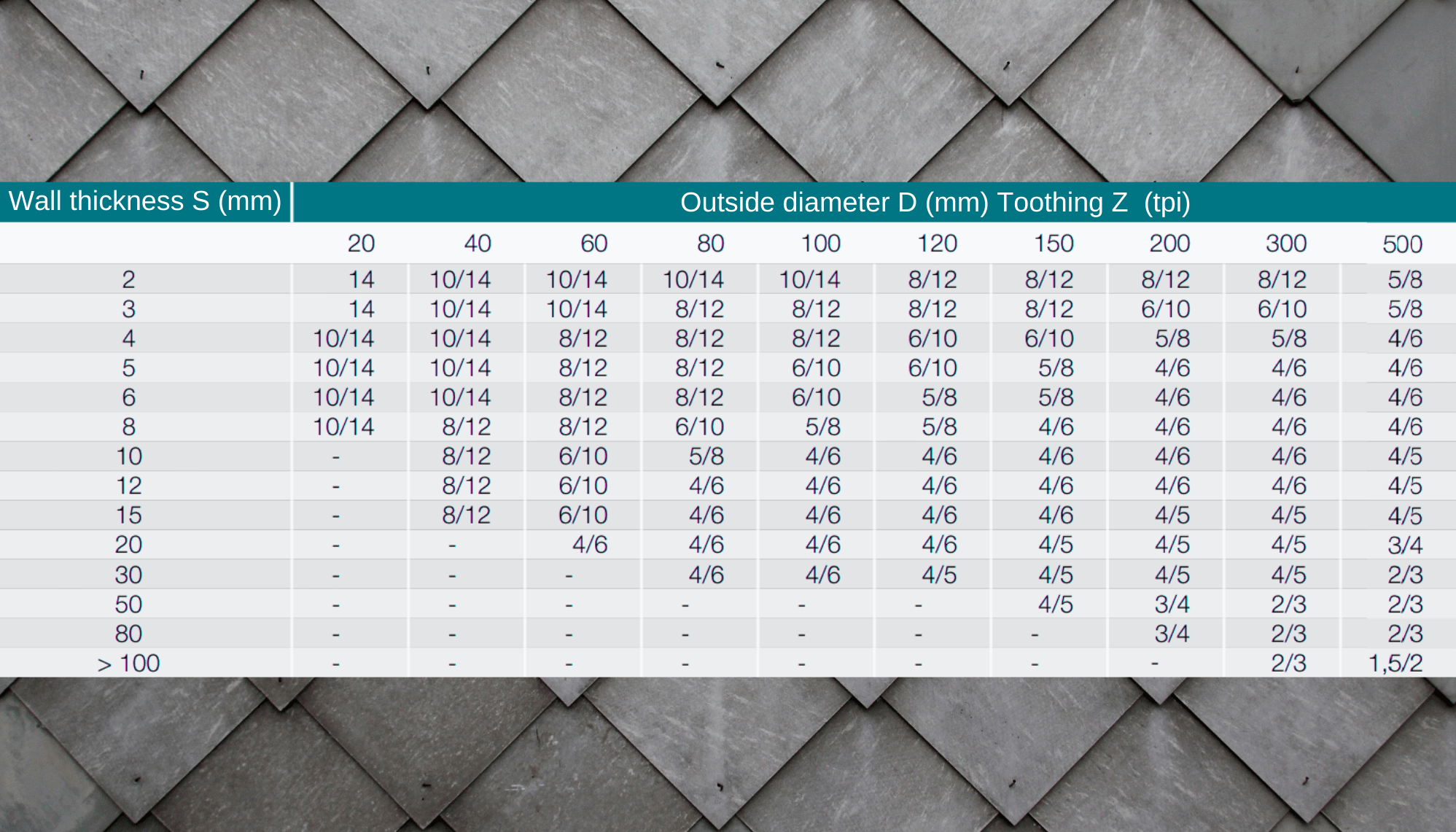

The choice of the right tooth has special influence on the cutting result on tubes and structurals. Variable tooth has provrn to be the most favorable tooth form. Tooth pitches selection depend on wall thickness and outer dimensions of tubes or structurals. The recommendations shown here refer to single cuts. If two or more tubes or square pipes are cut at a time, double wall thickness to select tooth pitch.

Different Sizes of Bandsaw Blades Production

To obtain optimum cutting rates, tooth pitch and tooth design are of great importance. we offer various tooth pitches to solve your cutting problems.

| Dimension (mm) | 0.75/1.25 | 1/1.5 | 1.4/2 | 2/3 | 3/4 | 4/6 |

|---|---|---|---|---|---|---|

| 27 * 0.90 | ||||||

| 34 * 1.30 | ||||||

| 41 * 1.30 | ||||||

| 54 * 1.60 | ||||||

| 67 * 1.60 | ||||||

| 80 * 1.60 |

: Positive rake angle of 10 or 16, the hook tooth has a large, long-drawn-out chip space. Therefore, it is mostly used for cutting non-ferrous metals, steels with a low content of carbon, Cr-Ni alloys, and primarily bigger cross sections.