Twin-Pillar Bandsaw Machines

When the head of a band sawing machine travels down on 2 posts, it is called a Dual Column type of bandsaw. The terms dual-column, dual-post, twin-post are used interchangeably. This design is great for cutting large parts while keeping the blade as straight as possible while the head is descending during the cut. This design keeps the blade from walking. They come in almost every size you could possibly want for cutting large pipe and structural shapes.

With dual column bandsaws, the blade enters the material at an angle, typically smaller than the scissor style machines, but cuts along the diameter of the material. Dual column saws are much more rigid than their pivoting counterparts due to the dual columns holding both ends of the head, resulting in near constant down feed pressure and feed speed across the entire width of the cut. This rigidity also reduces vibration, resulting in a better cut quality and a longer blade life. Twin pillar sawblades also take the shortest route through the material, decreasing the time required per cut and increasing production numbers. While dual column machines produce better cuts faster, they also tend to have heavier price tags. However, the increased cost can be quickly recovered by the increase in production numbers. This larger investment usually makes sense for more demanding production lines working with larger materials. For the metalworking industry, the double-column band saw is the most machine type in the band saw inventory.

Twin-pillar Bandsaw Machines Categories

Unlike Horizontal bandsaws, twin-pillar machines are commonly categorized into 2 groups: Semi-automatic and Fully automatic. There is no manual twin-pillar bandsaw machine ever manufactured.

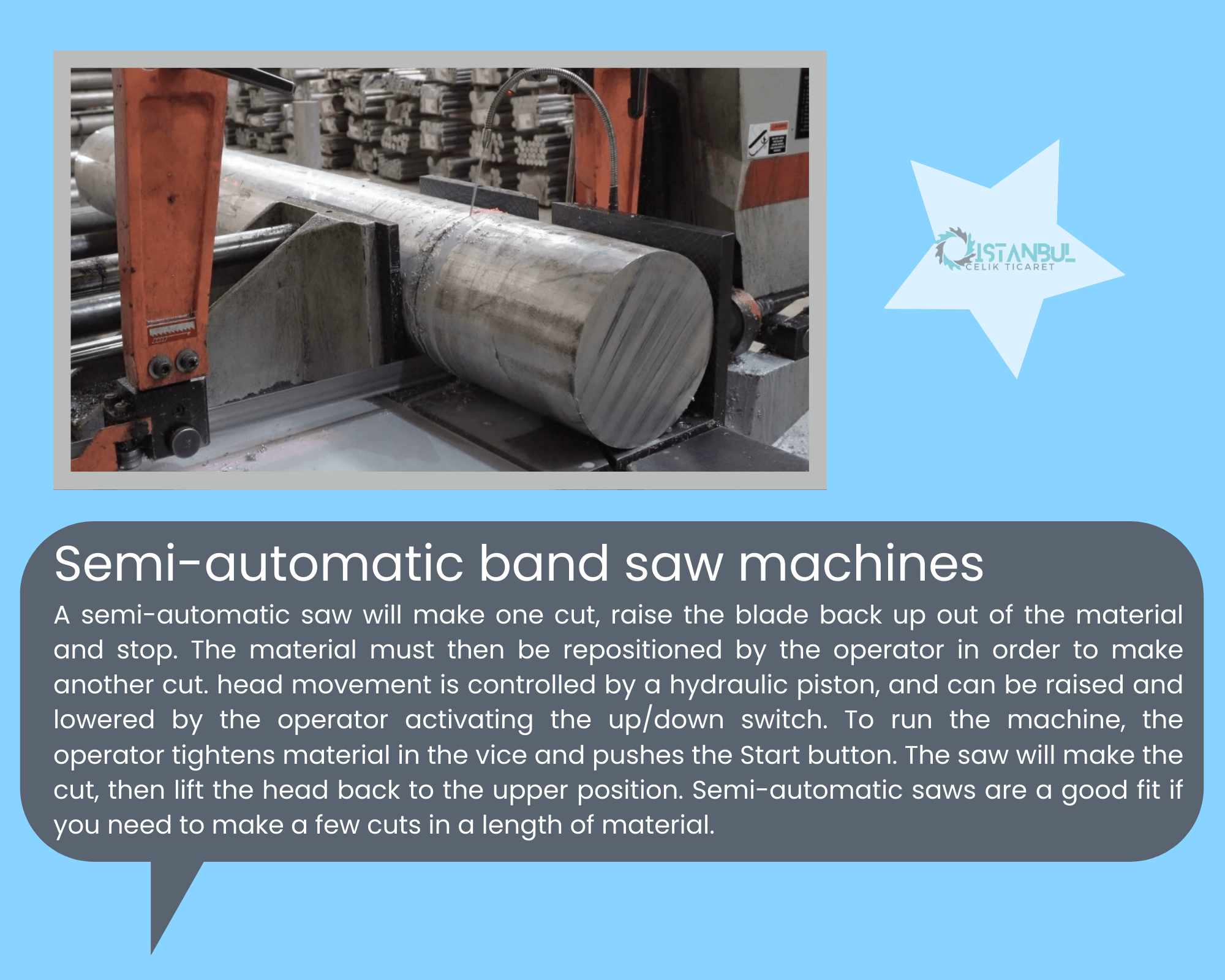

Semi-automatic: Semi automatic saws require the operator to move the material manually for each cut whilst the saw takes care of the cutting with automatic gravitational downfeed and head return.

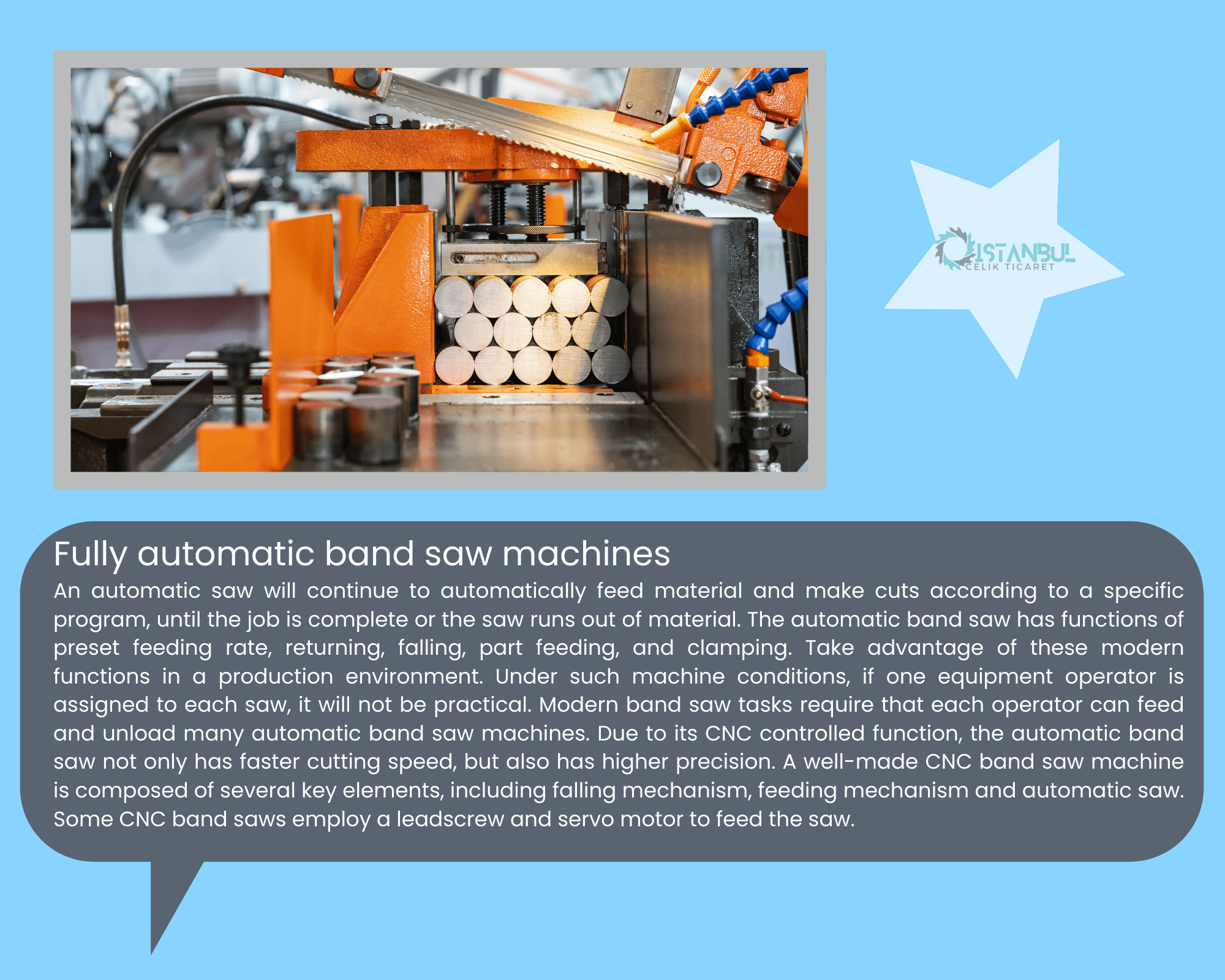

Fully automatic: Automatic saws are fully programmable and ideal for mass production cutting and can be left unattended for overnight production.

Parts of Band Saw Machine

- To avoid some harmful impacts on human health, a bandsaw machine is generally equipped with brushes or brush wheels for being able to prevent chips from getting caught between the blade teeth and causing damage.

- In order to cool the saw blade, the bandsaw machine must be designed and equipped with a cutting fluid circuit containing coolant liquid. The coolant liquid can wash away the waste material chips while keeping the saw blade cool as well as properly lubricated.

- Furthermore, the band saw machines which are controlled by PLC or CNC systems can be partly automated as well.

- Some automatic band saw machines that are equipped with digitally operated control units cannot just cut faster, but also cut in a more precise manner with higher accuracy, and eventually perform complex cutting operations like bevel cutting tasks.

- As a result, most of the modern bandsaw machines are pre-equipped with digital CNC controllers in order to adapt to today’s manufacturing requirements and standards.

If you are thinking of buying a new bandsaw, it's important to consider the following features:

When choosing a machine it's vital you get the sizing right. For example, a manual HD 375LR machine will cut 375mm and will cut a diameter of 300mm, but it's always best to add a bit on to your calculations as you don't want to have a machine working at its limit. Remember that if the machine mitres, this will cut down the capacity too, so you need to budget for that as well.

When buying a machine, it's important to decide if you want a manual machine, a hydraulic lift machine, a semi-automatic or an automatic bandsaw. The more expensive machines will lift up automatically after the cut, saving you time and effort if you have a lot of cutting to do.

You can choose machines that mitre left and right, or which mitre both left and right. If you are looking for a cheaper machine and don't need many mitre cuts, you could select a machine that mitres one way, and if necessary, flip the material to mitre the other way.

Blade speeds are very important in deciding which machine you need. The cheaper machines have two speeds -the slow speed is usually around 35 metres per minute and the fast speed is around 70 metres per minute. This is acceptable for stainless steel and mild steel. However, if you're cutting a wide variety of materials, you can choose a machine with a variator and the machine blade will cut at a numer of different speeds to suit all metals.

The more expensive machines, will clamp the work automatically - when you press the start button, they go down, cut the piece, go back up and unclamp. All you need to do is to feed the material through and press start.