Wood Cutting Bandsaw Blades

When it comes to bandsaws, woodworkers have a lot of options in front of them. Completely different from a hand-held saw or a chainsaw, a bandsaw is a power saw that uses a long, thin, toothed blade made of metal to slice through pieces of wood.

Working with lumber can be tricky using manual tools, which is why the bandsaw is a must-have power tool for any woodworking shop. It creates the perfect uniformed cuts every time.

Hereafter, we will try to perfectly describe what a wood bandsaw should have and do.

Wood Bandsaws lifetime

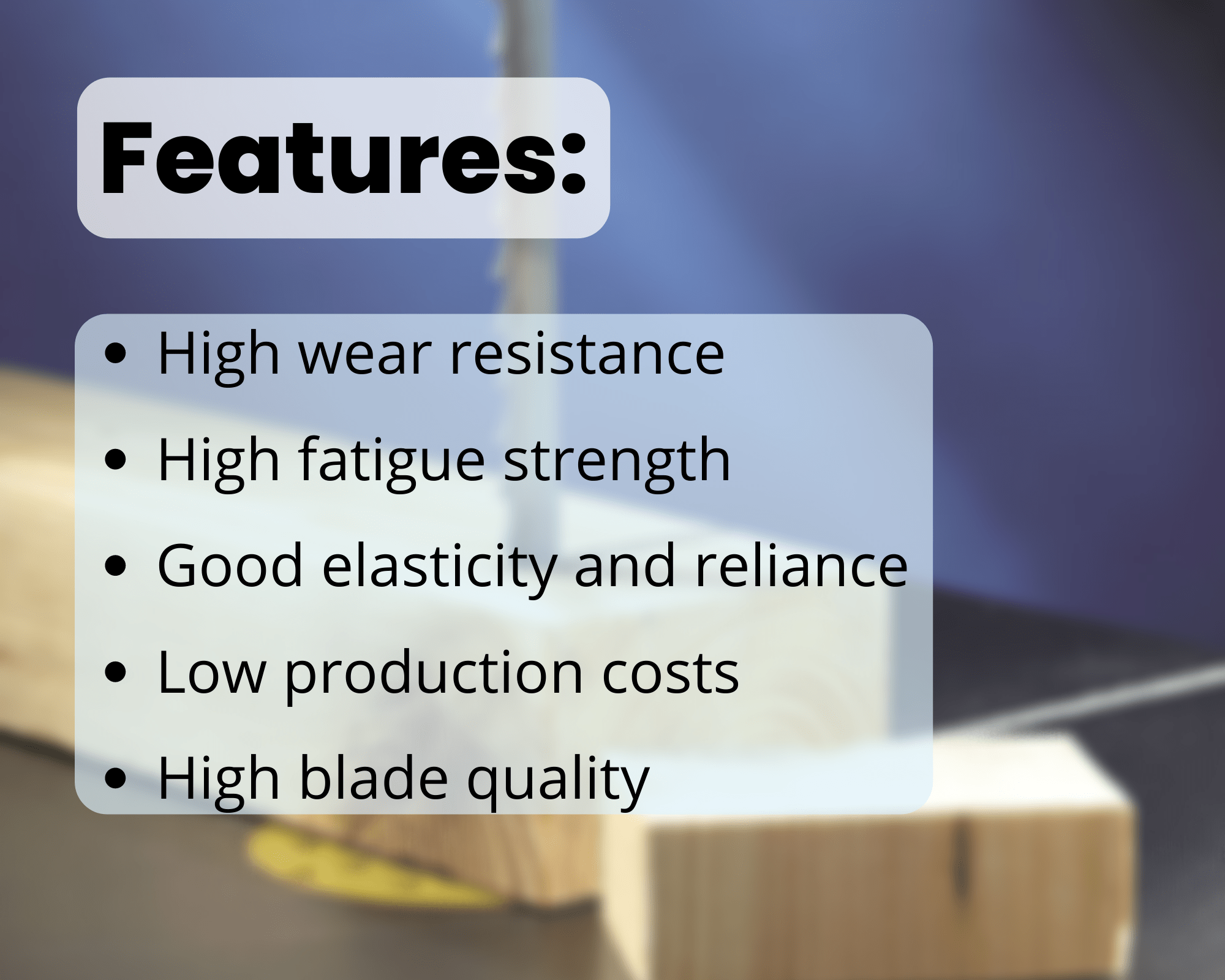

Wood bandsaw blades have a tough life. They are subjected to severe stresses. Teeth hitting the wood at extremely high speed give rise to shock stress. Everyday a blade runs over bandsaw wheels several hundred thousand times exposing it to high fatigue stress. Heat, particualrly at the edges of the teeth, creates thermal stresses, which must be absorbed by the rest of the saw blade to avoid distortion.

A bandsaw blade must be able to keep its set and remain straight whilst being subjected relatively high and varrying temperatures. Our experience ensures that bandsaw steel has the right combination of hardness and flexibility for the job.

An Important Note To Hit The Target!

There is a wide range of what is considered correct for tooth patterns on a woodcutting bandsaw. The general rule is that fewer teeth per inch provide a faster, but rougher cut; and more teeth per inch provide a smoother, but slower cut.

Blade Choice Recommendation

- For cutting tight curves (less than 5⁄8 " radius) and delicate, thin materials, use a 1⁄8 " or 3⁄16 " 10–14-tpi standard-tooth blade.

- To cut curves greater than 5⁄8 " radius, or when cut quality matters more than speed, use a 1⁄4 " 6-tpi standard- or skip-tooth blade.

- For general ripping and crosscutting, use a1⁄2 " 3-tpi standard- or hook-tooth blade.

- For resawing, use the widest 3-tpi skip- or variable-tooth blade your saw accepts. Typically, the wider the blade, the straighter it cuts.

- Cutting green (undried) wood requires the widest 2–3-tpi skip-tooth blade your saw accepts.

- Dense, abrasive exotic wood species cut best with a carbide-tooth blade. It will stay sharp longer than a steel or bi-metal blade.